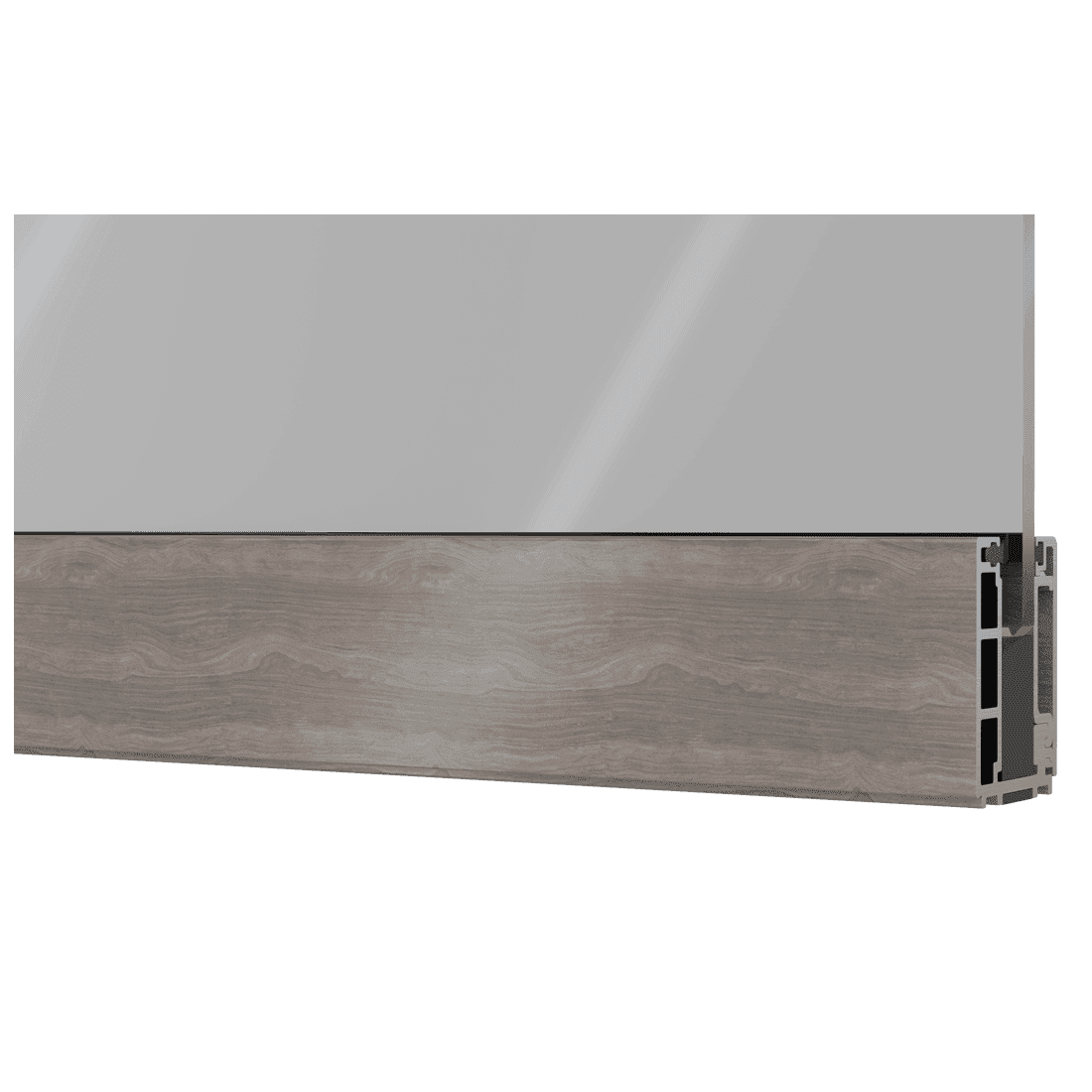

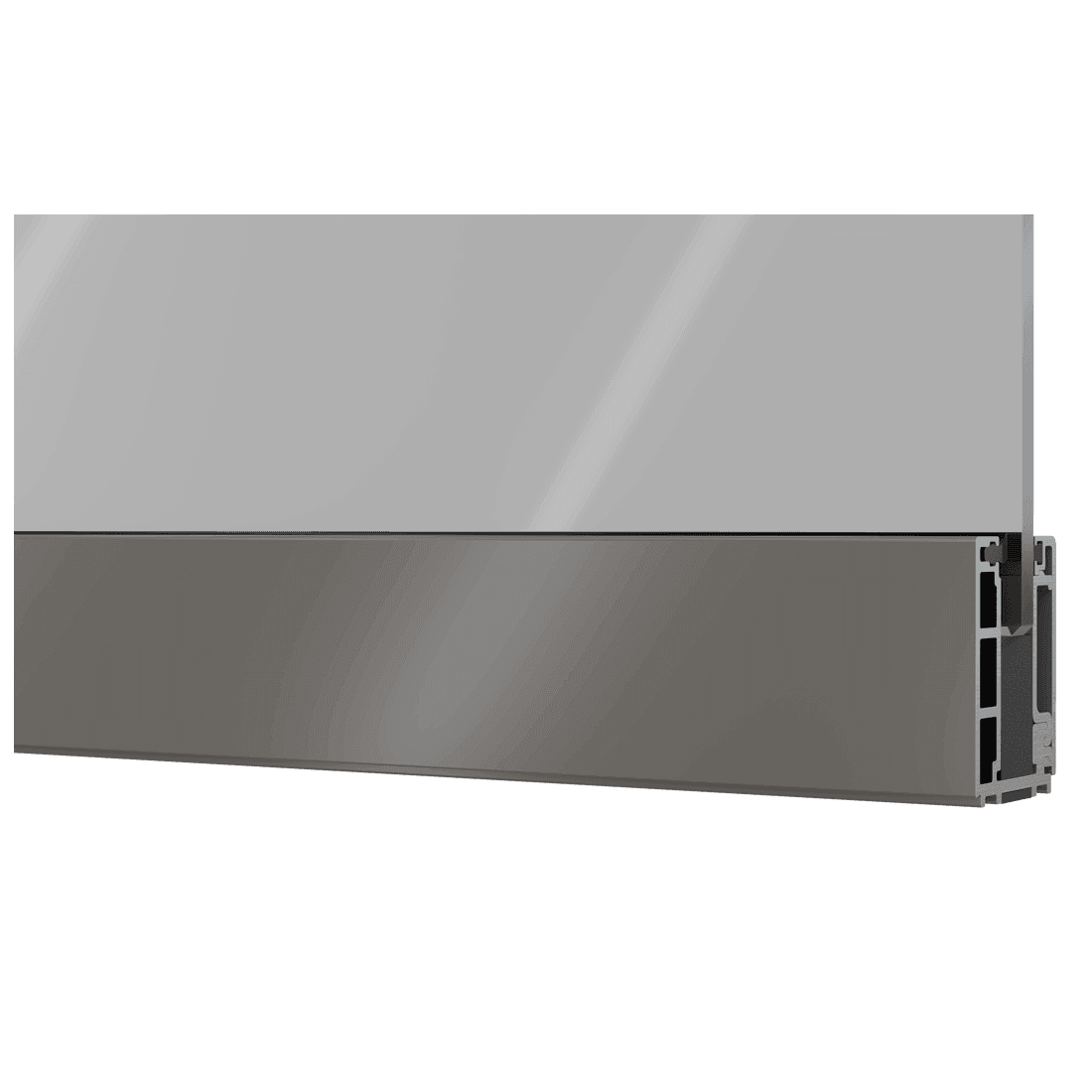

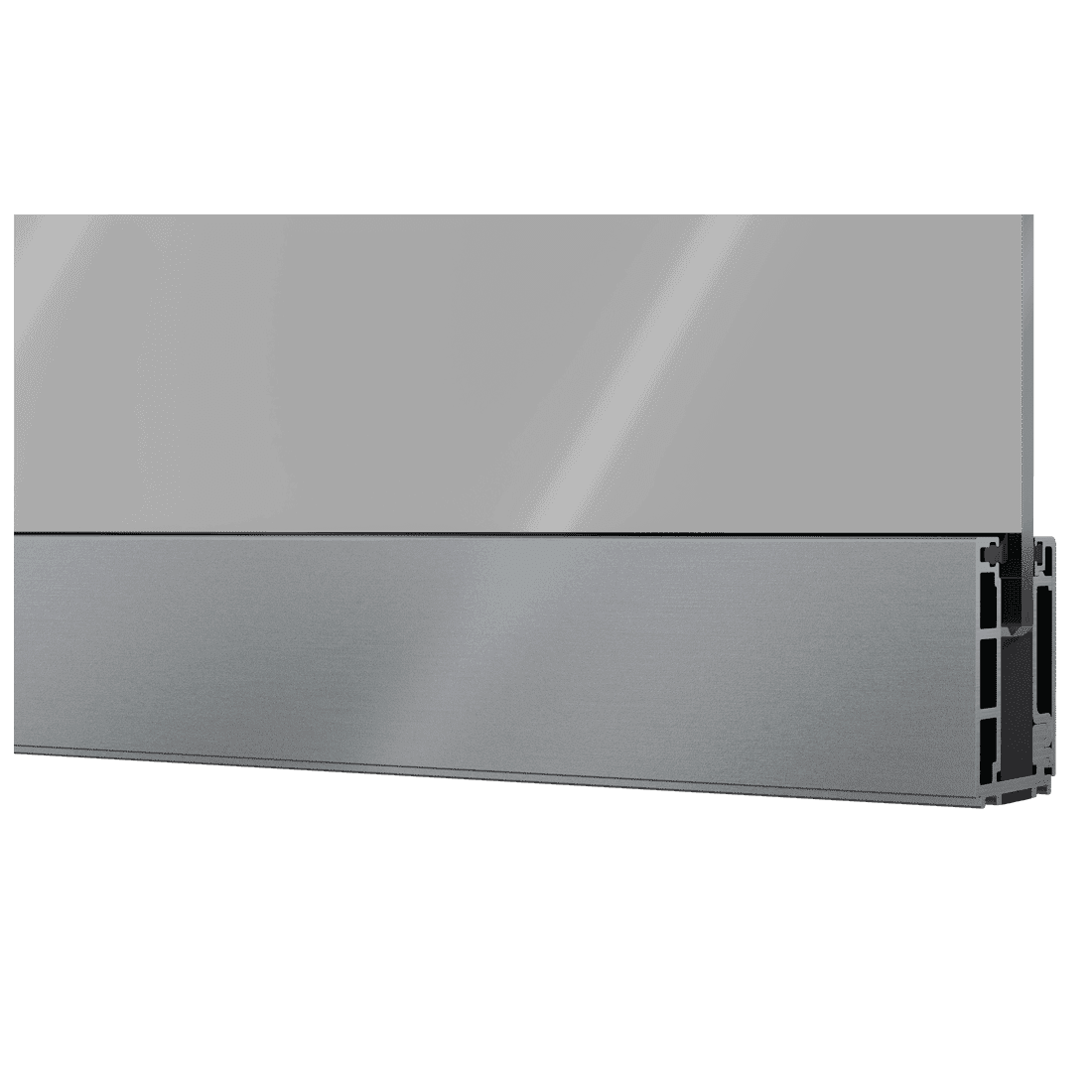

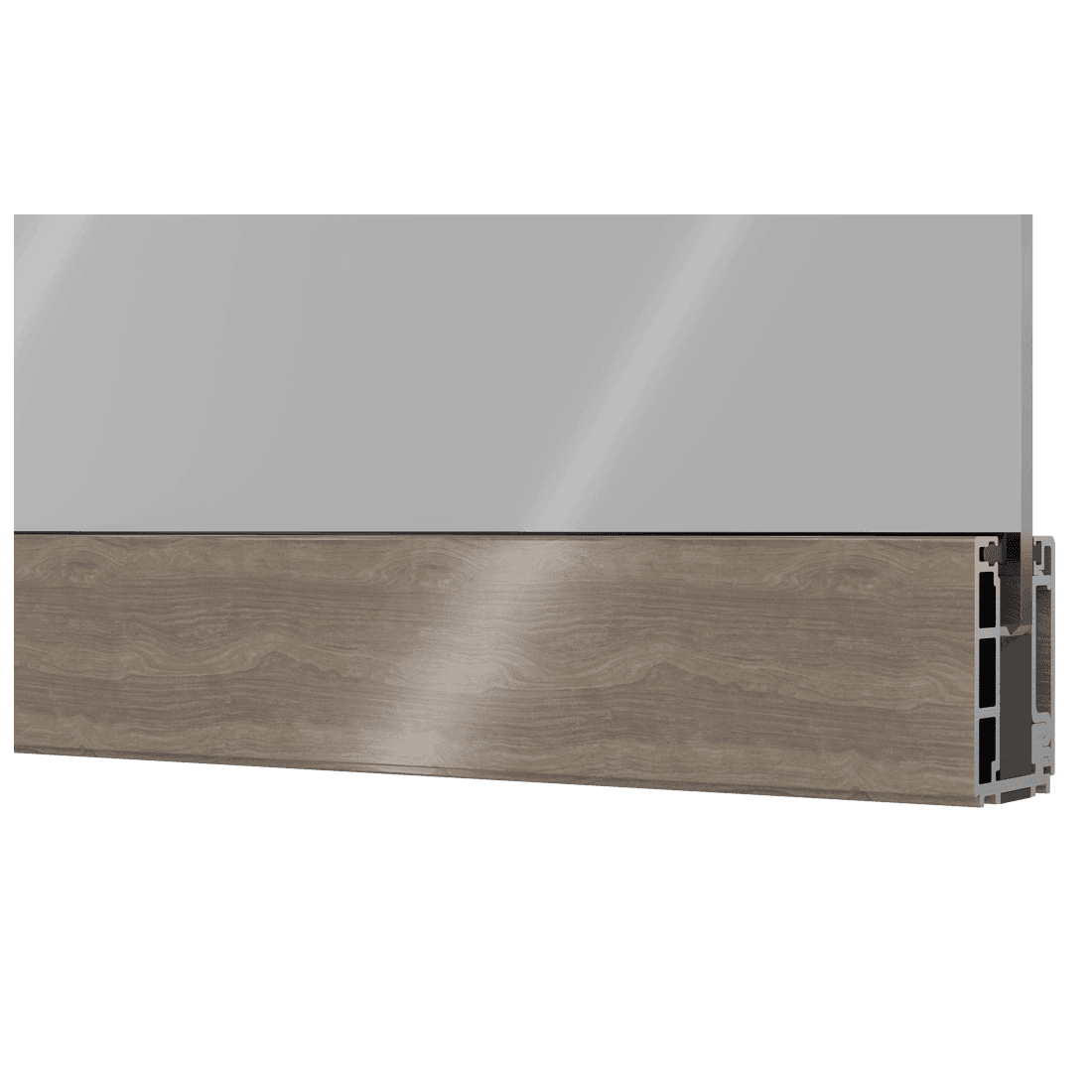

alnoplan G50

- It has an economical and easy-to-install structure.

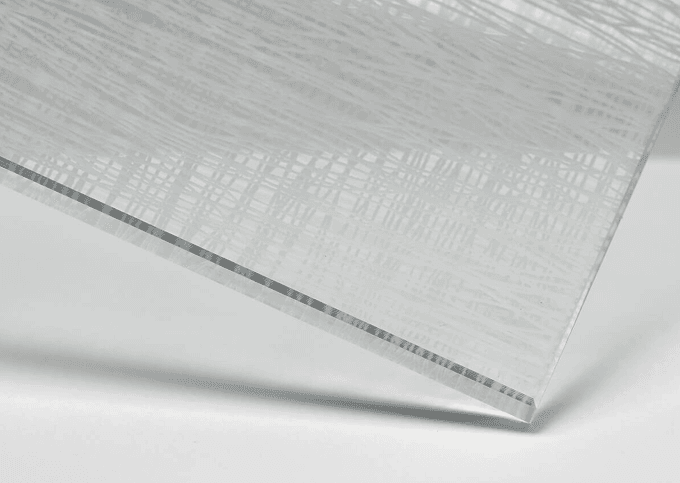

- It is produced using 10 mm tempered glass.

- Not suitable for blind systems.

- Alternatively, strip film coating can be applied.

- It can be applied in different sizes and shapes.

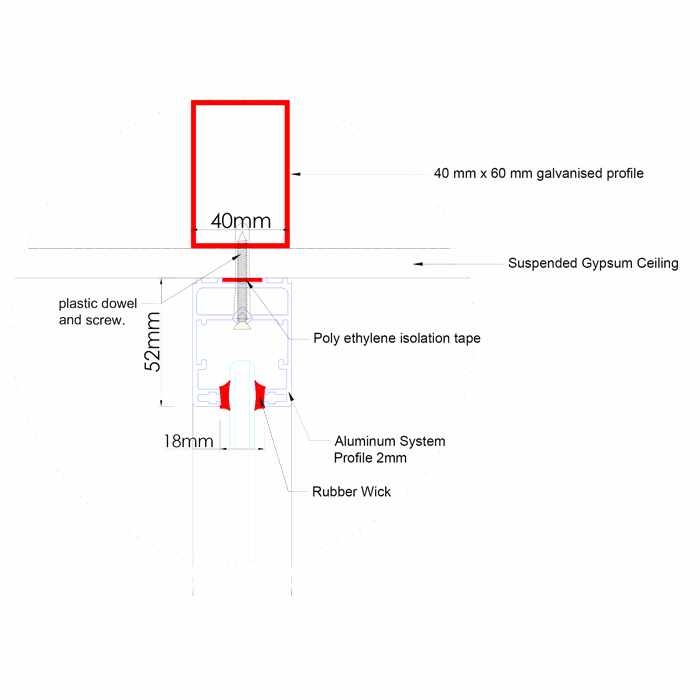

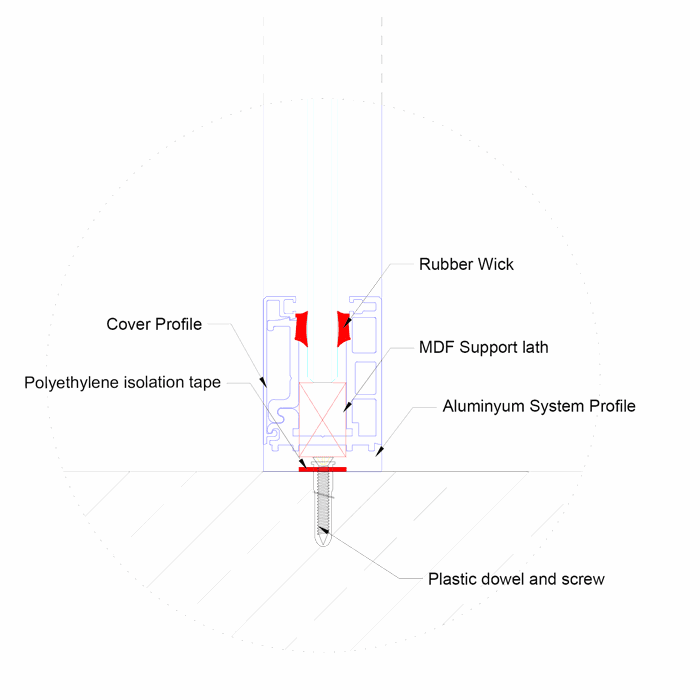

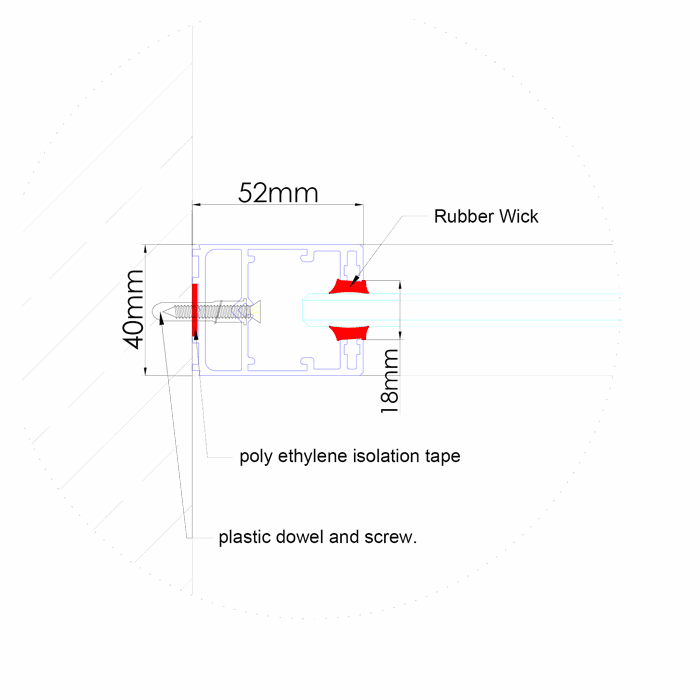

- Profiles are first laid in accordance with the project.

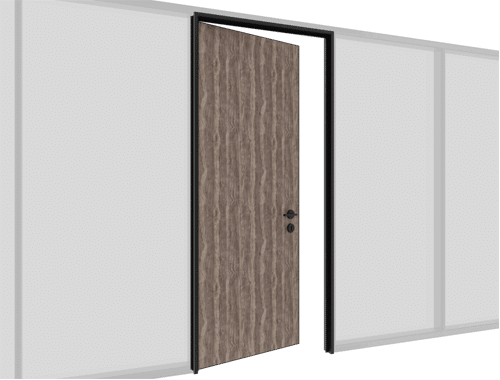

- Door frames are placed at the points required by the system.

- The assembly process is quick and practical.

System Thickness

System Weight

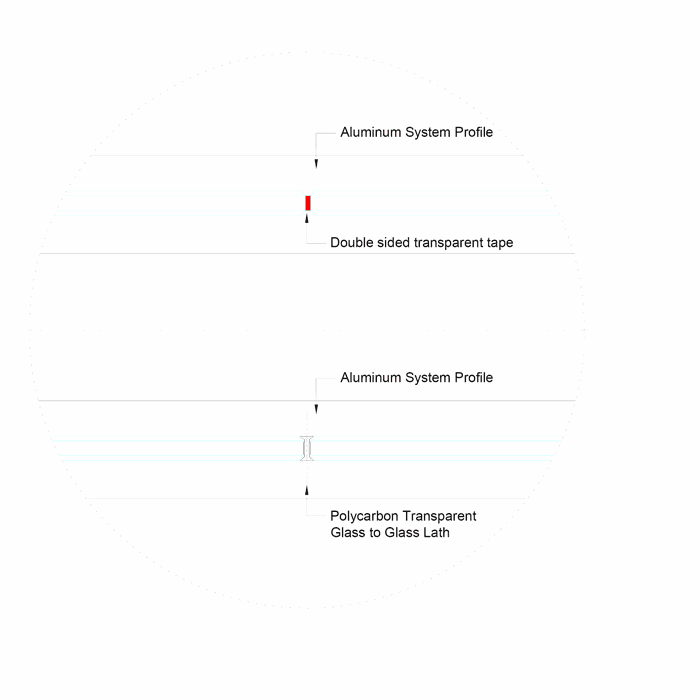

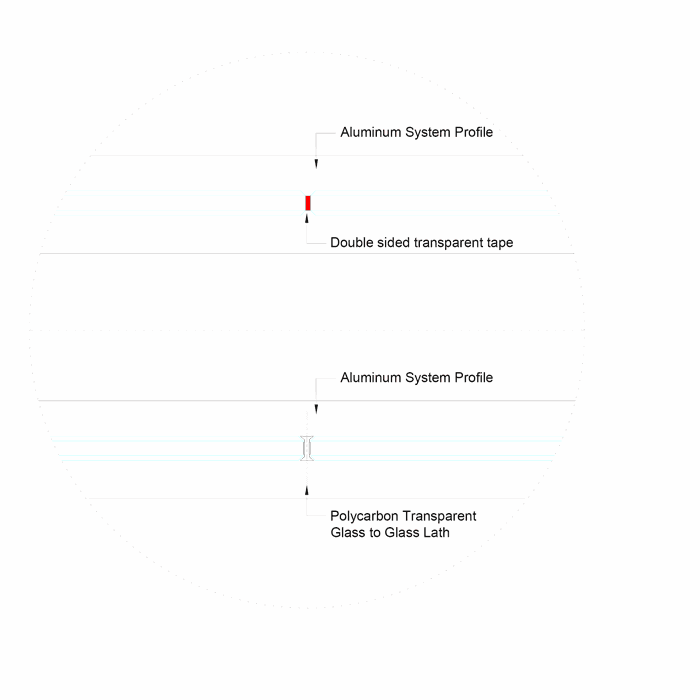

Joint Detail

Glass Surface Thickness

Insulation

Jalousie

Unit Dimensions

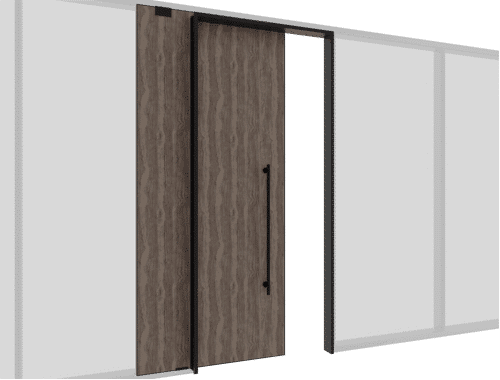

Door Accessories

Door Type

System Operating Temperature

Wingspan

Wing Height

Full Panel Option

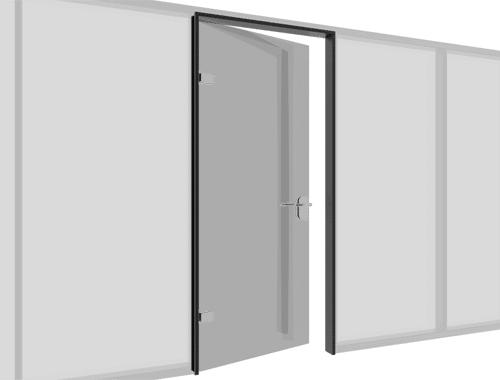

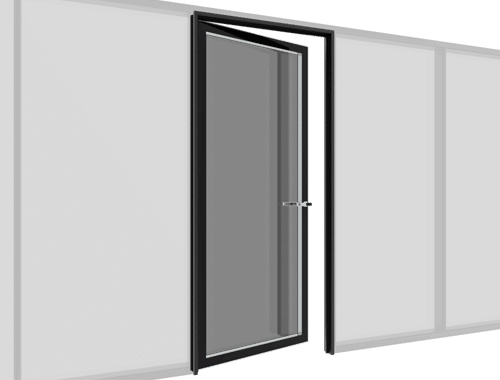

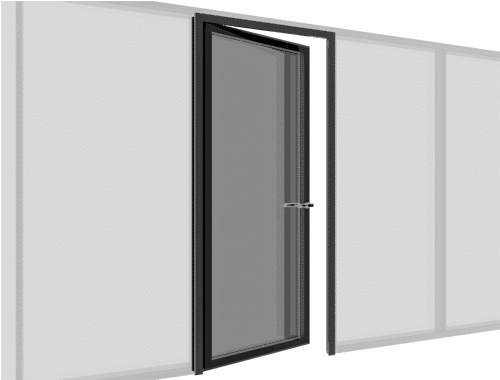

Door Opening Directions

Glass measurements are taken and ordered. Once the glass panels arrive from the factory, they are installed.

If 4+4 or 5+5 non-tempered laminated glass is used, they can be sourced from stock and the installation can be completed immediately (excluding door glass). After that, only the door glass needs to be awaited.

In single-glass systems, there are various quality options available. For instance, by using acoustic laminated glass, sound insulation can be achieved—up to 38 dB, although not as much as with double-glass systems.

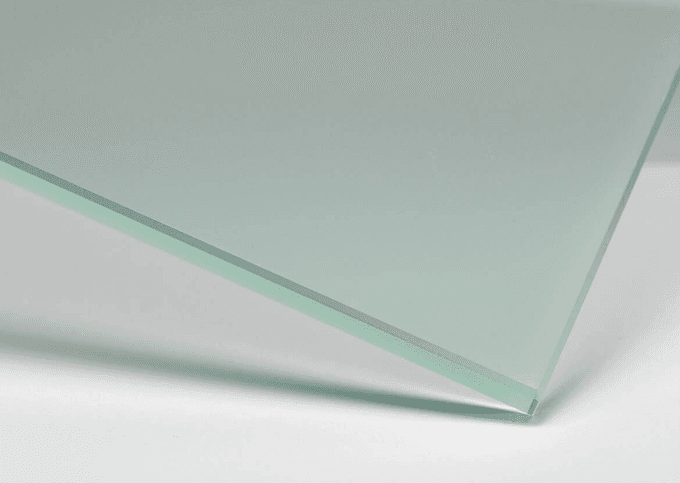

If high-quality glass is desired, extra clear glass can be used.

When acoustic glass is used and the partition wall is installed over a raised floor, a 10 cm wide stone wool-filled sound barrier should be placed under the floor, and a stone wool-filled sound barrier should also be installed in the ceiling directly above the partition walls.

In this case, it would also be beneficial for the glass doors to be manufactured with a double-glazed structural design.

If an acoustic system is desired, additional measures must be taken on the glass doors as well—such as adding sound insulation seals to the door frames and installing a sound barrier at the bottom of the doors.

One of the most important aspects for all partition walls is the choice of accessory brands. There are reputable global companies in this area, and using these brands’ handles, locks, and hinges helps minimize malfunctions. This reduces the risk of accessory failures and eliminates the need for frequent maintenance.

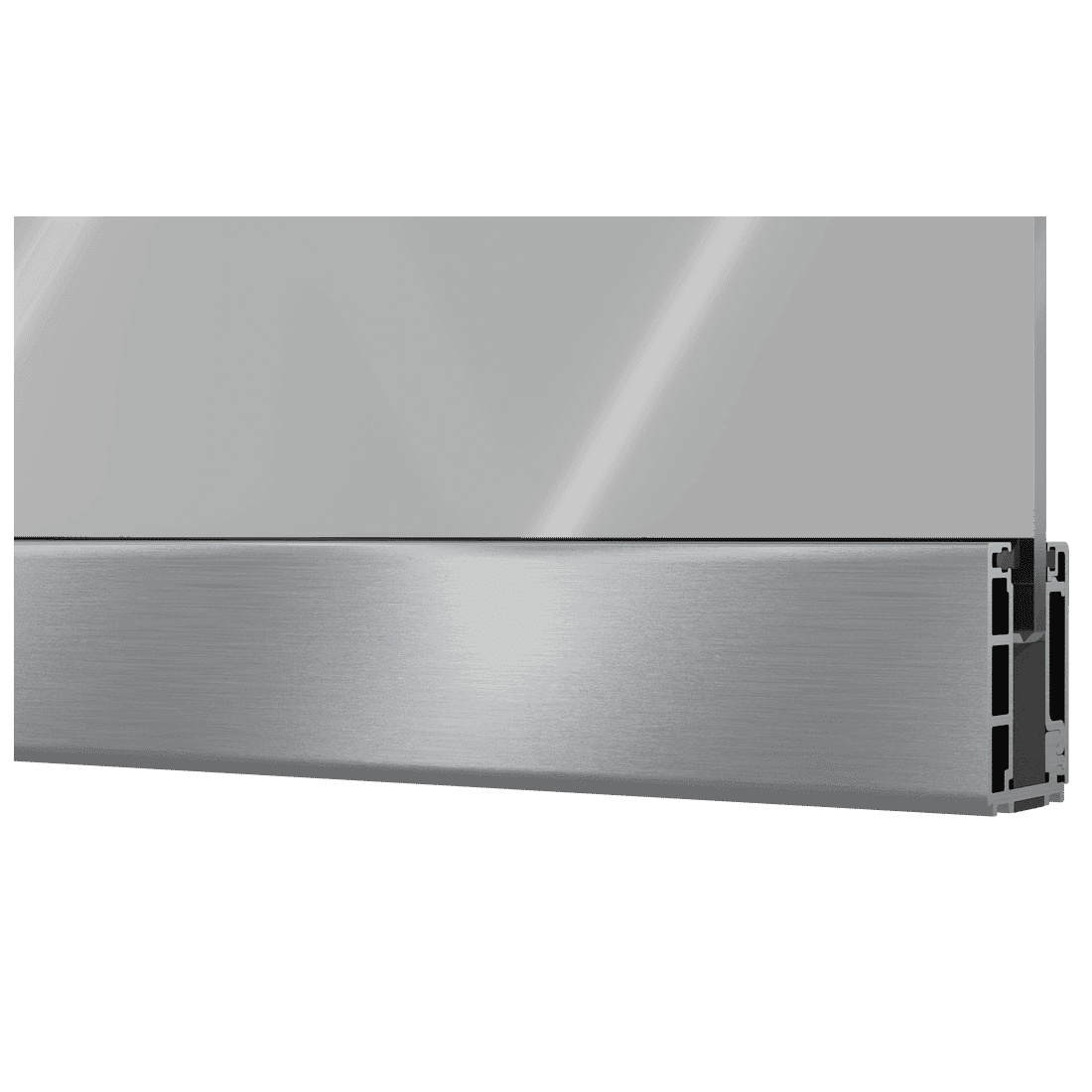

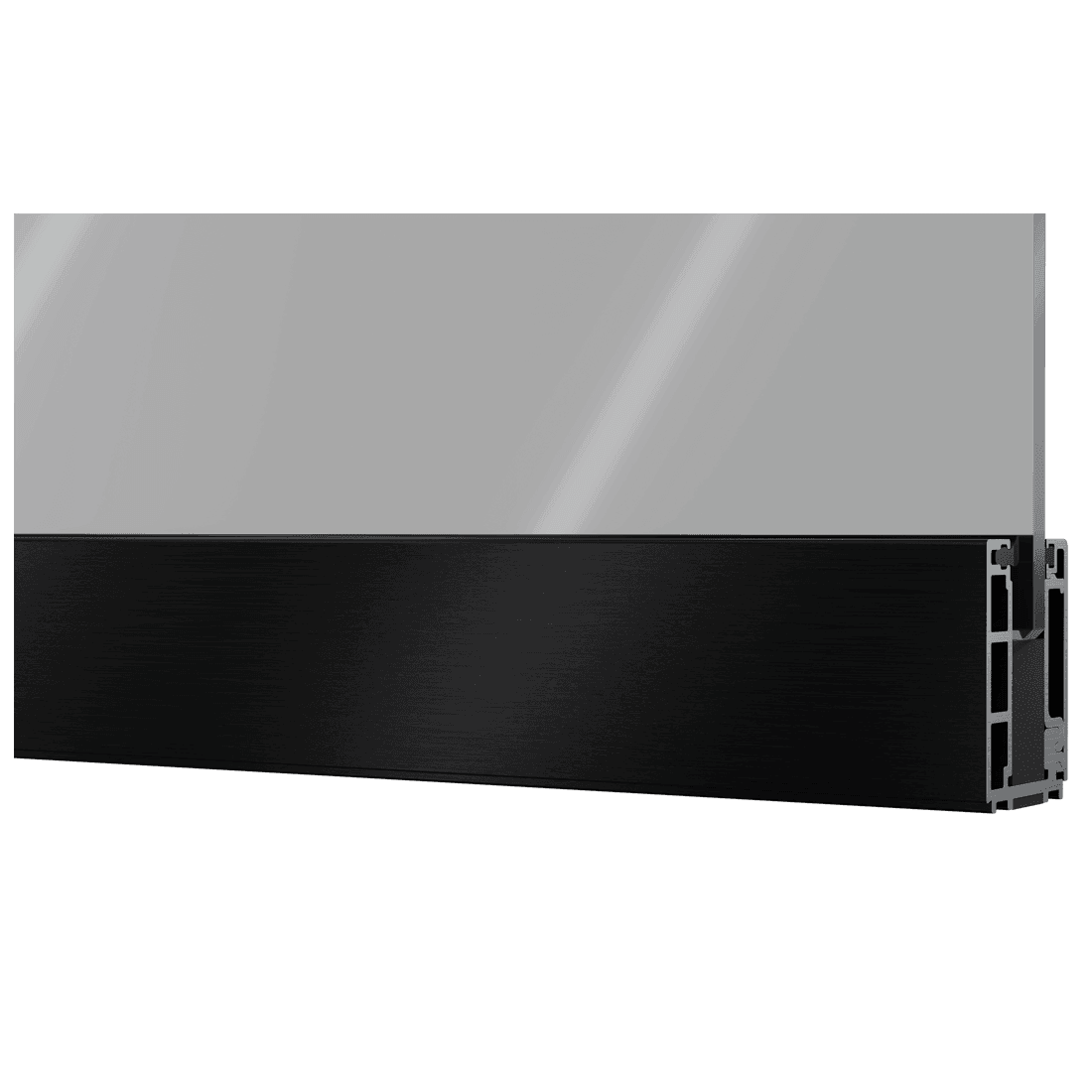

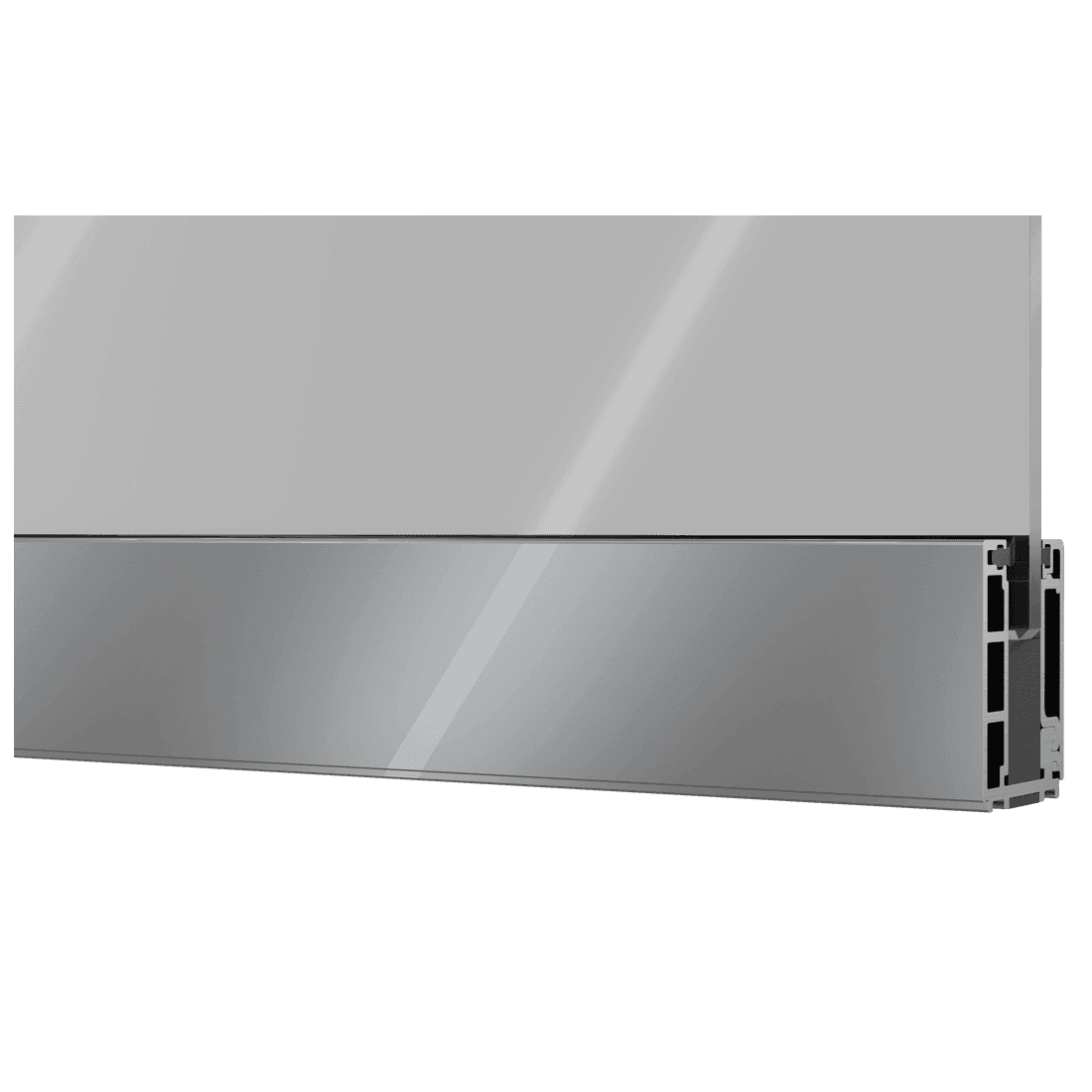

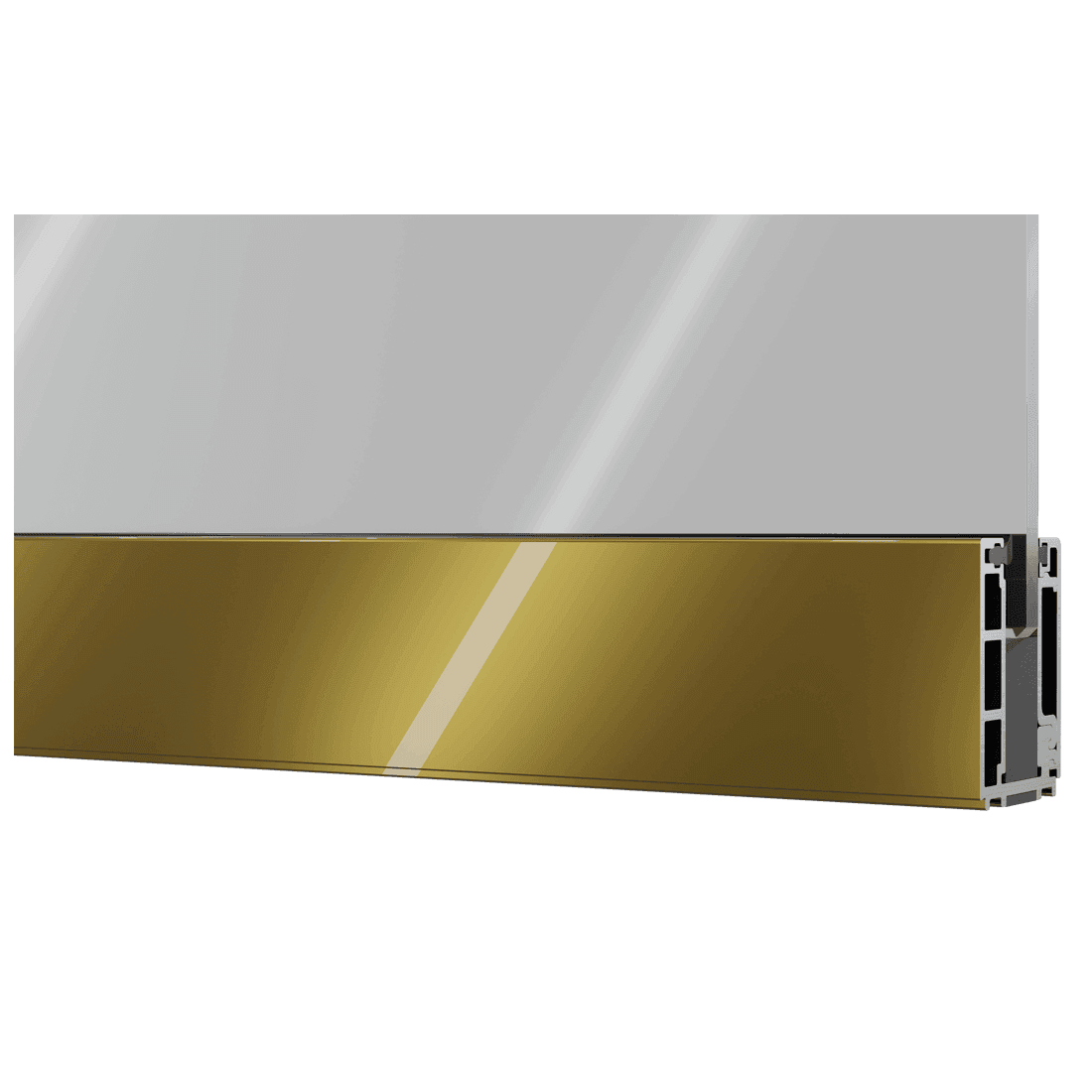

Aside from these technical aspects, architects may also request the aluminum profiles to be coated in various colors using electrostatic powder paint in order to match other decorative units in the design.