alnowall Movable Partition

- It offers large volume areas for mass events.

- It is found in places such as hotels, hospitals, universities and cultural centers.

- User comfort and functionality are prioritized.

- Flexible planning is made to suit future needs.

- It includes various usage areas such as conference and meeting rooms.

- It can also serve as a theatre, opera and wedding hall.

- It offers architectural solutions suitable for use by large masses.

- It is designed with a modern and aesthetic design approach.

- Product Documents

When designing these halls, acoustic calculations must be made using wall partition panels and movable wall partition systems to evenly distribute sound across the entire space in situations where the sound must not scatter—such as during speeches, concerts accompanied by various instruments, or singing.

When the acoustic calculation of a conference hall is done correctly, it becomes possible to hear the sound from the stage equally from every part of the hall.

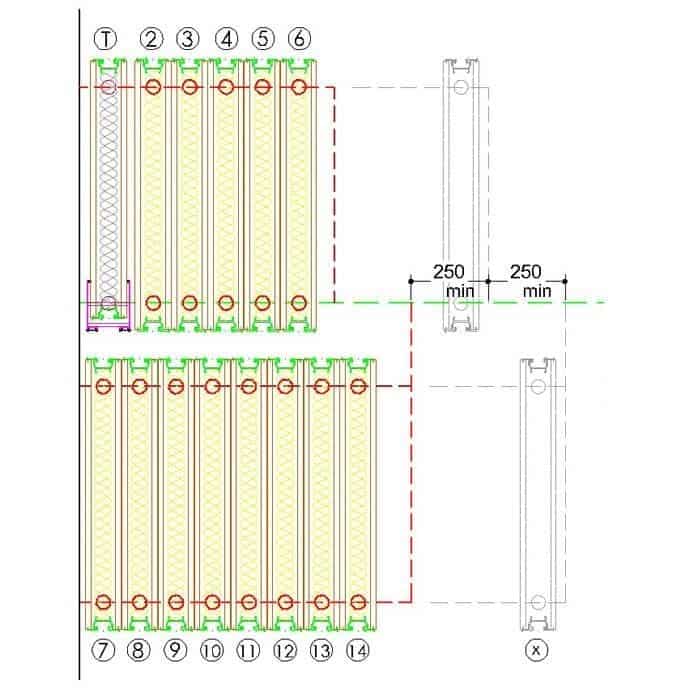

Since halls are generally designed for multi-purpose use, when different events take place simultaneously, they are adapted to be divided into smaller and distinct sections within the general acoustic values.

We refer to the materials used to temporarily divide these spaces—and to restore the hall to its original form once the event is over—as movable partition walls.

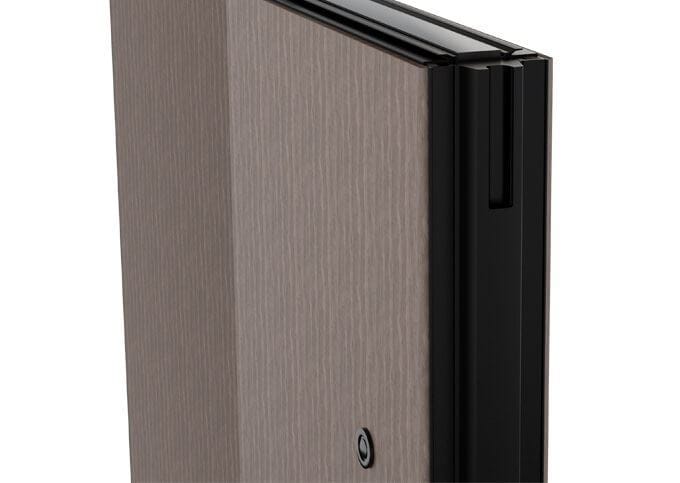

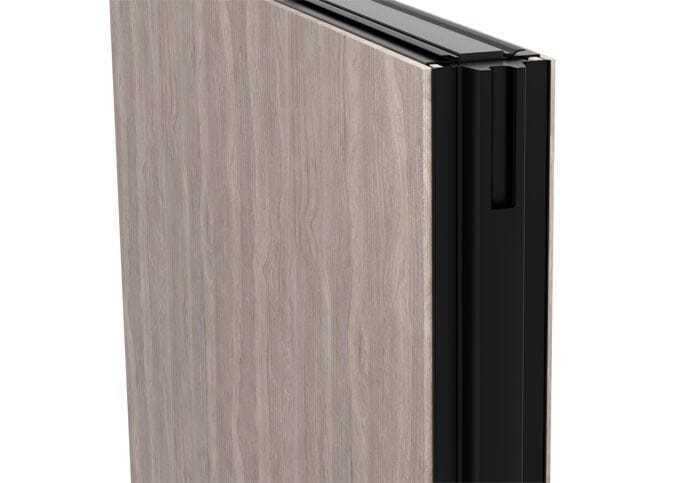

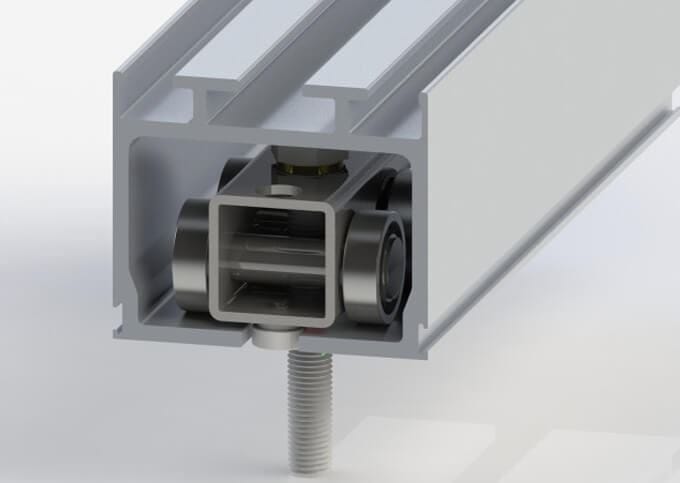

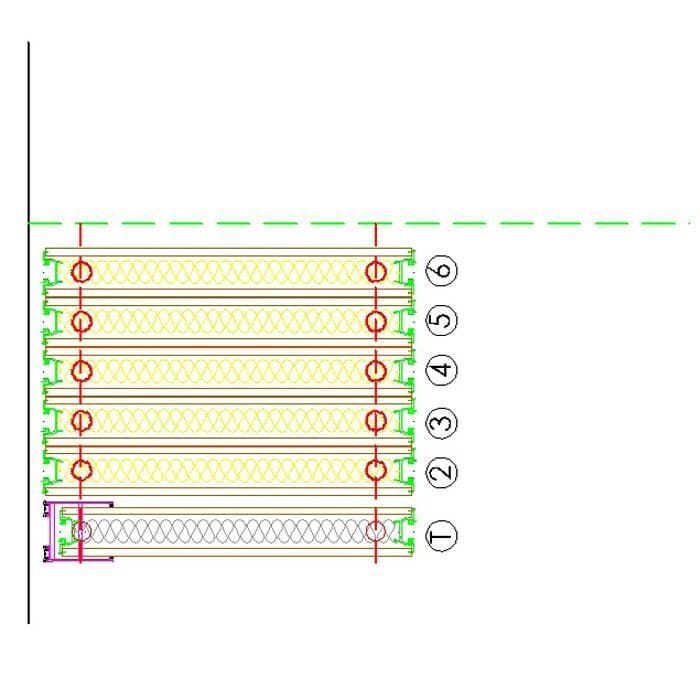

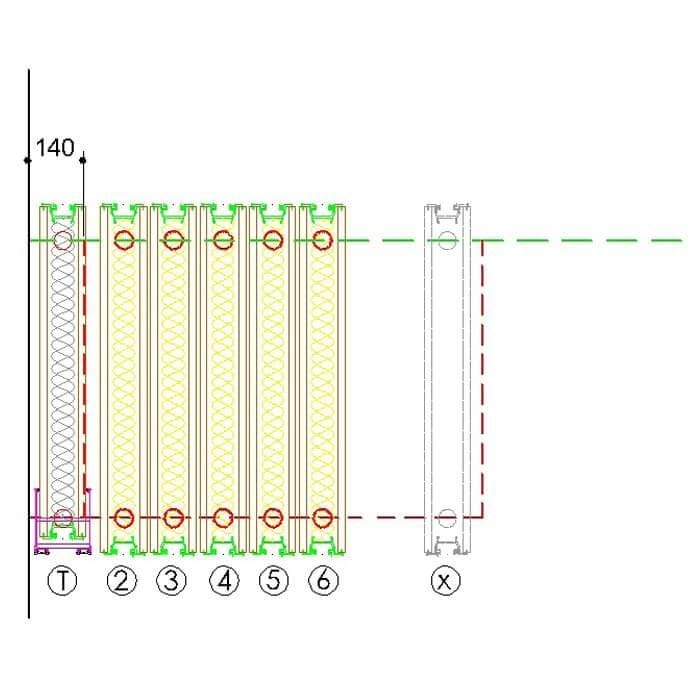

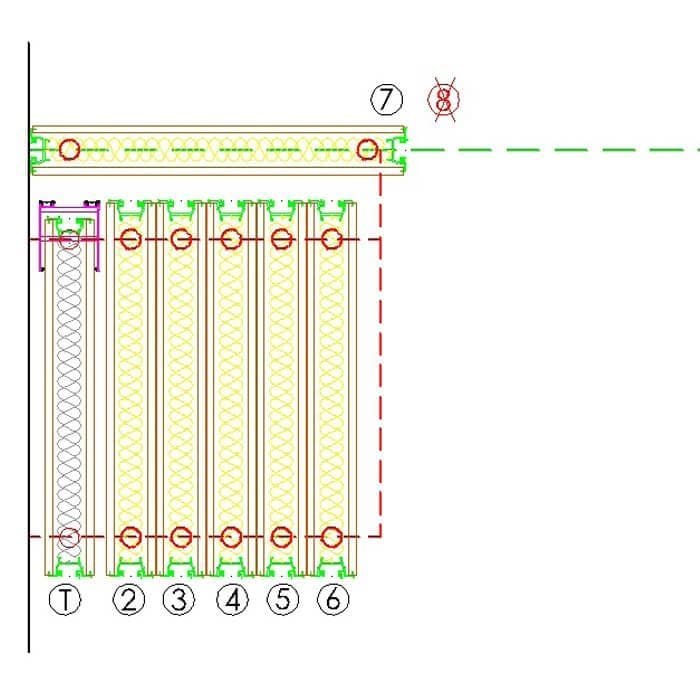

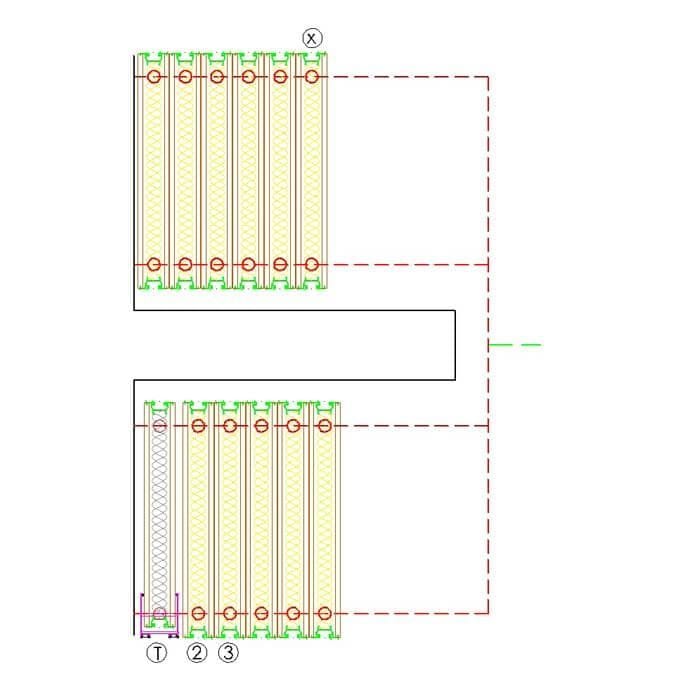

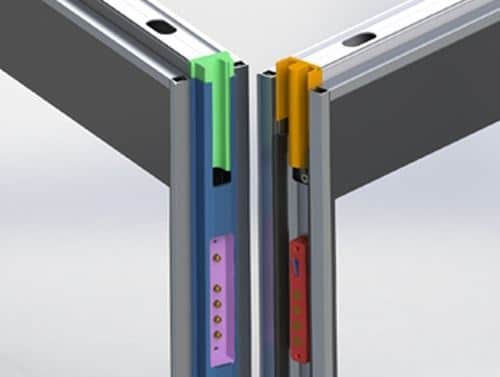

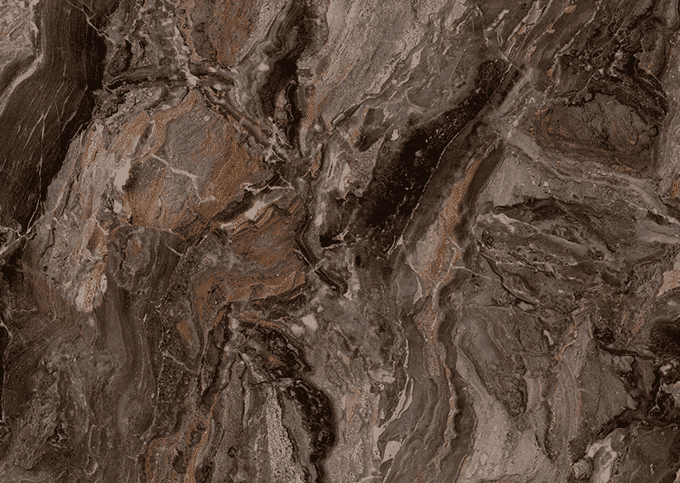

Movable partition walls and intermediate partition systems, by their physical construction, consist of panels made from a frame of aluminum profiles filled with sound-insulating materials. The exterior is covered with protective materials such as laminated chipboard or MDF-lam. These panels are designed with acoustic calculations in mind, containing materials like rock wool, wooden partitions, sound insulation felts, cork boards, wall partition systems, and stainless steel sheets to absorb sound and prevent transmission. When lined up side by side, they form a temporary solid wall.

A hotel ballroom construction site, with a height of 6.6 meters, includes two double-winged doors.

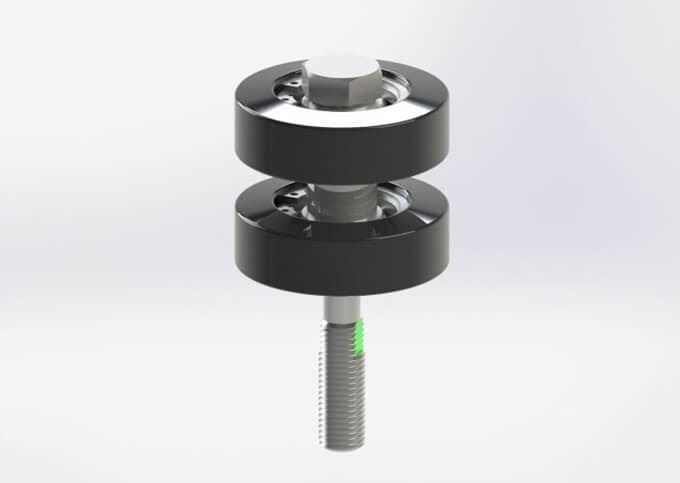

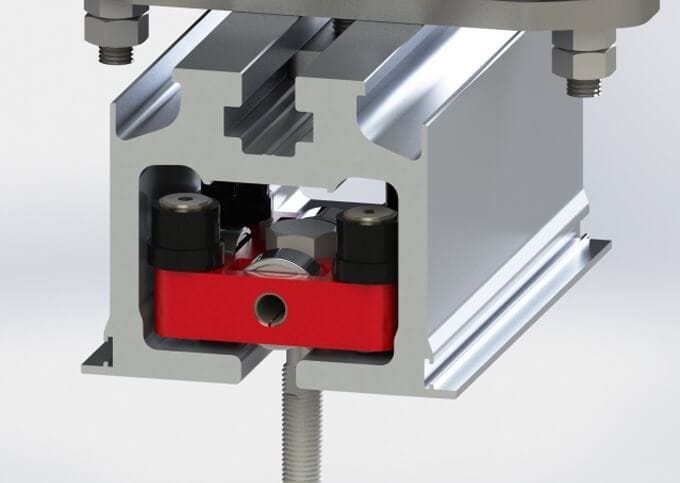

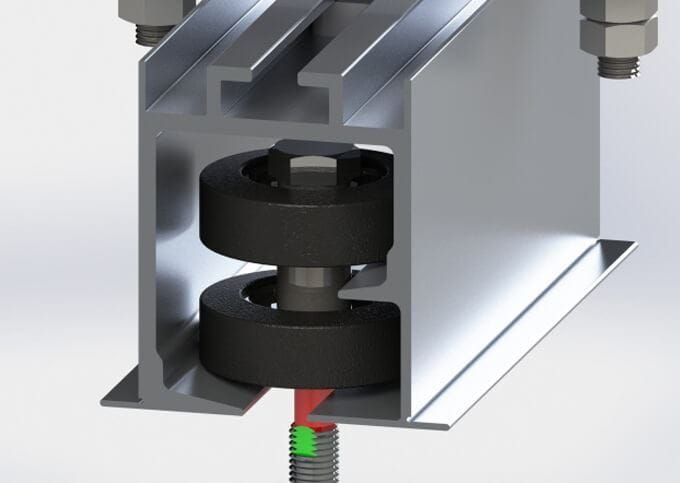

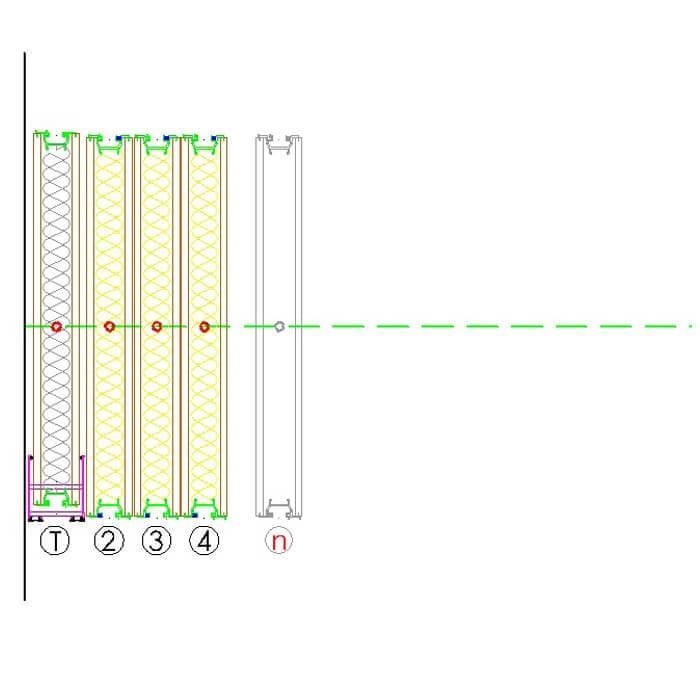

From a technical perspective, this system involves a rail track on which the panels move in sequence, suspended and fixed to a steel structure. The panels are moved between two walls along the rail, and the bottom and top sliding mechanisms move up and down to anchor the panels to the floor and to each other.

To achieve sound insulation, the bottom and top edges of the wall partition systems, intermediate partition systems, and wall partition panels use sliding mechanisms that create a sound barrier by pressing against the floor and the overhead rail. Locking the final panel creates a stable, sound-insulating wall.

The width of the panels ranges between 80 and 110 cm, and their height can vary between 2.4 and 12 meters. The tallest panel our company has manufactured so far is 9.45 meters. Our movable partitions have been used in over 100 hotels, hospitals, conference halls, and wedding venues across the country.

For better understanding, here’s an example: movable partitions can be used under a 25-meter-wide space frame ceiling on the floor. They can divide a 1000 m² area into 8–10 sections, each transformed into classrooms for instruction. When desired, all the panels can be moved to the parking area, converting the space back into a conference hall.

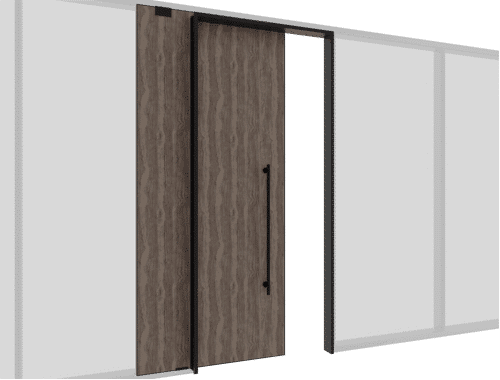

The exterior designs of movable partition walls and wall partition systems are shaped according to the requests of architects. Some panels are covered with carved and molded surfaces made by furniture makers, while others feature decorative finishes using mirrors or stainless steel sheets. The design decision is made by the project architect.

Movable partition walls and wooden partitions are generally manufactured within the 45–57 dB sound insulation range. Each additional dB requires a separate internal material layer. The choice of these materials is determined based on the acoustic calculations to be made.

Types of Movable Partition Wall Systems

a. Manual:

Panels are manually moved and fixed to the floor using a cam mechanism or jack system.

(Example: A manual movable partition wall application in a hotel.)

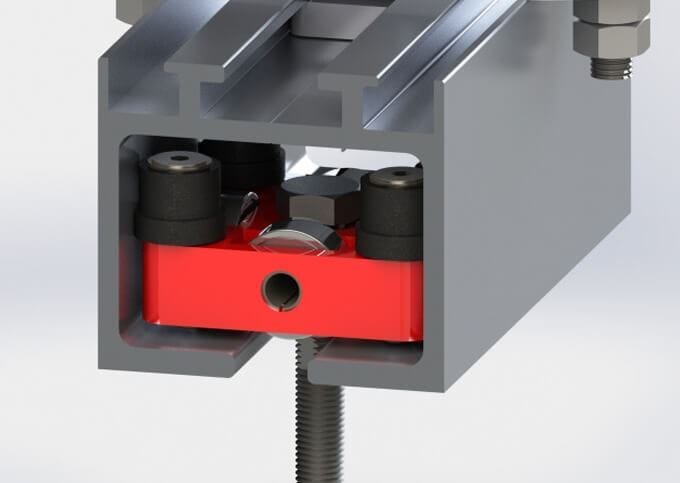

b. Semi-Automatic:

A system where the panel sliders are moved by an electric motor and the panels are locked to each other using magnetic devices.

(Example: A semi-automatic movable partition wall.)

c. Fully Automatic:

A system in which the panels are taken from the parking area by a chain mechanism on the panels and sequentially aligned using the same mechanism to form a fixed wall.

As Altınbölme, we manufacture manual and semi-automatic movable partition wall systems. Although fully automatic systems are produced globally, they are not widely preferred due to their high cost.

Manual systems are produced with solid surfaces on both sides due to their internal mechanism structure.

Semi-automatic systems can be manufactured up to 6 meters high using double-sided jumbo glass panels, providing a wide viewing area between two halls. A 15-meter-wide semi-automatic wall can be opened or closed in just 1.5–2 minutes.

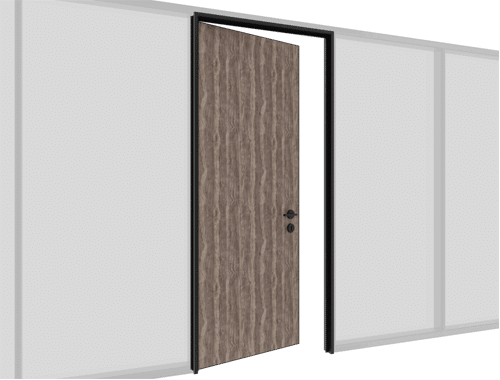

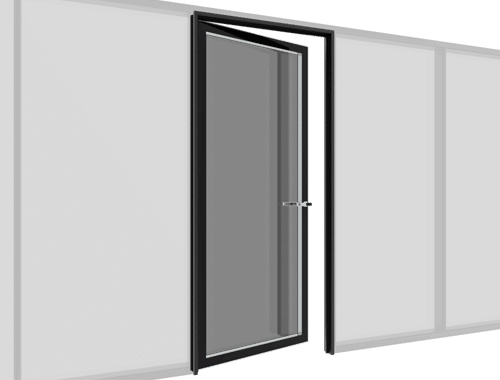

When movable partition walls are fully closed, access is provided via single or double-winged doors. In compliance with regulations, some facilities require them to be manufactured as fire-resistant (30’-60’). In such cases, panel surfaces are made from fire-resistant materials and coated with fire-resistant varnish.

We continuously strive to support our architects and project offices in their designs regarding intermediate partition systems and movable wall partition systems, offering assistance through preliminary inspections and detailed drawings.